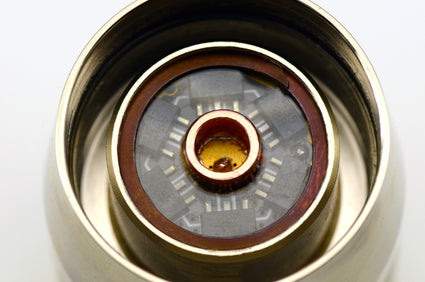

Alphas are uniquely constructed with a solid, single-piece head for unparalleled thermal performance and durability. It also features our proprietary Icarus driver that is fully user programmable.

If you want a light that just works, there is no better choice.

You'll trade a smaller form factor for about 1/3 the run time. We don't offer these very often, but you can also use a "Shorty Body" accessory with any Alpha.

I tried carrying other keychain lights. They were handy to have around, but always got ditched from my key ring...because when I need light I don't want it stuck to a wad of keys.

Other keychain lights just didn't work like I needed them to, so I came up with something that does.

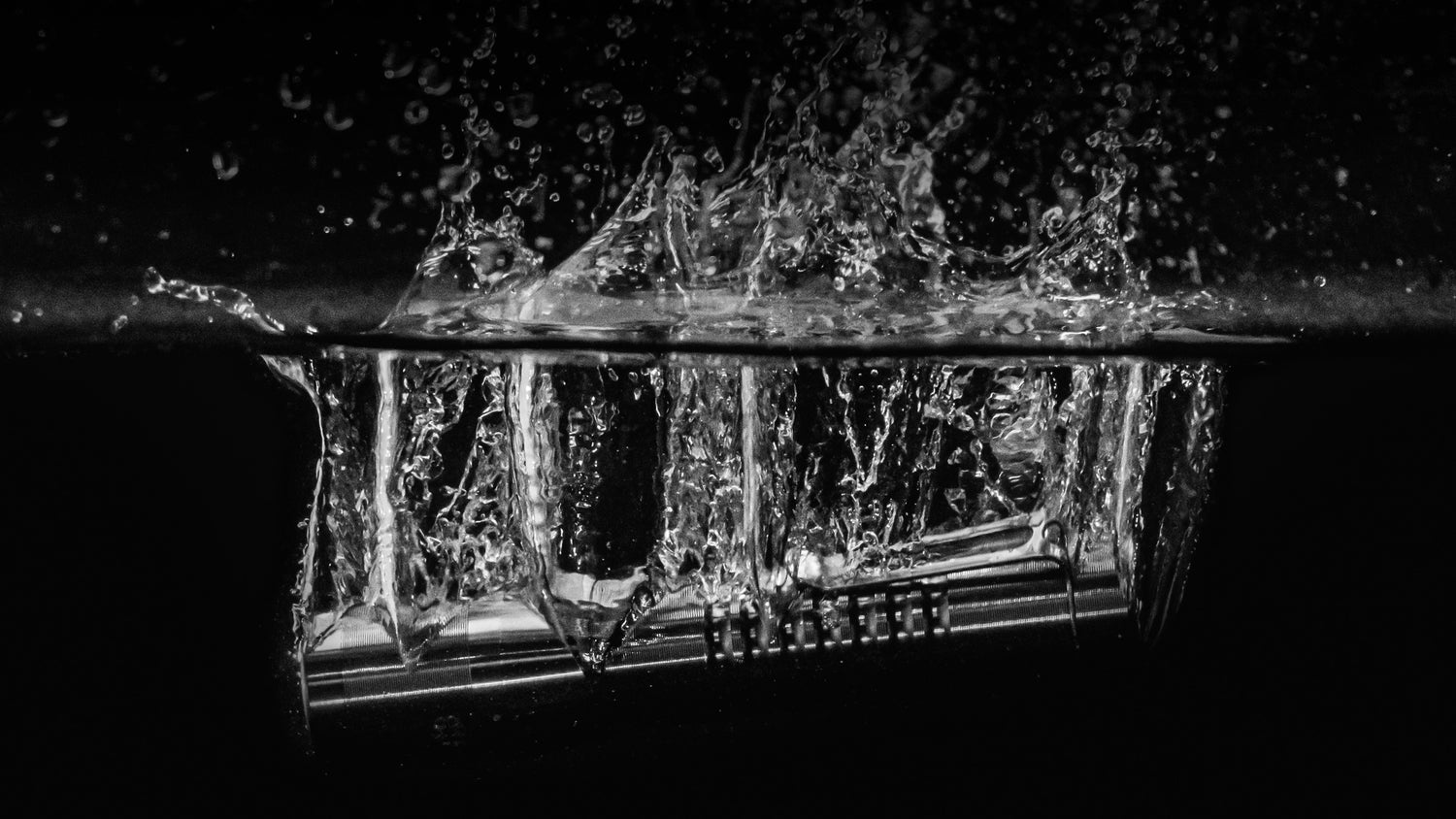

The exposed fins on the solid copper pill transfer heat directly to your hand and the environment instead of trapping it inside the light.

The Delta is our newest light and boasts the power of an Alpha in a smaller package.